It may be summer, but now is the time that many schools, offices, healthcare facilities, and manufacturing plants are planning maintenance and repairs for the next season. It’s crucial to have a boiler in working condition before the cold kicks in. A challenge for many buildings is deciding what boiler parts need to be repaired or replaced.

Upgrading boilers with energy-efficient burners is easily justified when you consider the impact that an Industrial Combustion burner can have on improved efficiency.

Why the upgrade?

Boilers function only as well as the burner runs. A boiler can be well-designed, but if it has a poor burner, you’d be better off with a poorly designed boiler and an efficient burner.

Burners combine fuel and air in a way that maximizes combustion efficiency and minimizes emissions. According to the U.S. Department of Energy, “An efficient natural gas burner requires only 2% to 3% excess oxygen, or 10% to 15% excess air in the flue gas, to burn fuel without forming excessive carbon monoxide. Most gas burners exhibit turndowns of 20:1 on oil and up to 35:1 on gas. A higher turndown ratio reduces burner starts, provides better load control, saves wear and tear on the burner, reduces refractory wear reduces purge-air requirements, and provides fuel savings.”

What are the risks of purchasing a standard burner?

There are many benefits of an efficient burner vs. a standard burner, but a key differentiation is that efficient burners have the right air-to-fuel ration during the entire range of firing rates, without constant adjustment. In other words, burners with complex linkage designs will not maintain air-to-fuel settings over time. Usually, they provide excess air to make up for a lack of burner performance.

Alternatively, many new burners use servomotors, which independently adjust the quantities of fuel and air brought to the burner head. The plus? The lack of linkage prevents hysteresis and gives accurate point-to-point control. By purchasing a new efficient burner, it will have controls that provide consistent performance and reliability as the burner becomes accustomed to different firing rates.

Burners that have single-point or proportional control should be avoided via linkages should be avoided. Why? Wear of the linkage joints is inevitable, and the rod-set screws can loosen. Slippage causes major declines in efficiency.

How to determine the potential energy saved by replacing your existing burner with an energy-efficient burner:

- First, complete recommended burner-maintenance requirements and tune your boiler.

- Second, conduct combustion-efficiency tests at full- and part-load firing rates

- Then, compare the measured efficiency values with the performance of the new burner.

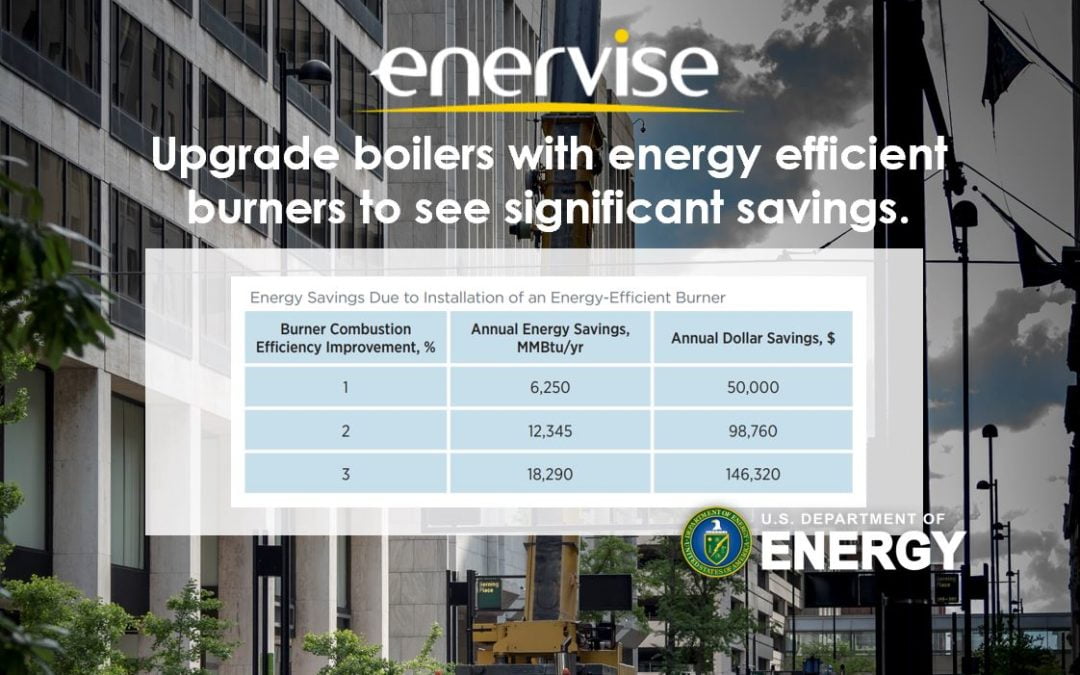

The U.S. Department of Energy states, “Even a small improvement in burner efficiency can provide significant savings.” They provide an example in which a 50,000 pound-per-hour process boiler has a combustion efficiency of 79% (E1). The boiler annually consumes 500,000 million Btu (MMBtu) of natural gas. At a price of $8.00/MMBtu, the annual fuel cost is $4 million. In this case, the savings from an energy-efficient burner is significant, even if combustion efficiency improves by just 1%, 2%, or 3%.

Cost Savings = Fuel Consumption x Fuel Price x ( 1 – E1/E2)

Energy Savings Due to Installation of an Energy-Efficient Burner:

- At 1% burner combustion efficiency improvement, the annual dollar savings = $50,000

- At 2% burner combustion efficiency improvement, the annual dollar savings = $98,760

- At 3% burner combustion efficiency improvement, the annual dollar savings = $146,320

If the installed cost is $75,000 for a new burner that provides an efficiency improvement of 2%, the simple payback on investment is:

Simple Payback = $75,000/$98,760/year = 0/76 year

Why Enervise?

We are an authorized distributor of Industrial Combustion Parts and Burners.

Enervise is the area distributor of Industrial Combustion (IC) burners and aftermarket parts. Our market stretches the states of Ohio, Kentucky and Indiana. If you want OEM parts for your burner, please contact us and we will be happy to assist you. To learn more, visit our Industrial Combustion Burners & Parts Overview.