-

Your building has a unique set of challenges.

That’s why we offer customized maintenance solutions based on your business, equipment, budget and goals. Our depth of expertise in providing quality service, repair, and maintenance and retrofit solutions builds long-term relationships with most of our clients. In fact, 95 percent of our clients renew their maintenance agreements with us for at least 11 years. We stay at the forefront of industry best practices and only hire and retain the best technicians in the industry who are trusted by hundreds of local building owners.

We can offer on-site/resident staffing and will customize full-service or performance-based planned maintenance solutions.

Contact our experts today to see what type of program will work for you!

-

Our planned maintenance programs

We’ll work with you and your building needs to design an HVAC/R & building controls maintenance program. With our services you’ll experience fewer failures, less costly repairs, improved comfort, extended equipment life and increased reliability and productivity.

Planned Maintenance: We customize a program matching ASHRAE rated maintenance tasking and frequencies to meet your goals.

Full-service Planned Maintenance: Under this plan we provide a thorough maintenance review with your internal team to assess your overall annual needs. With a full-service plan, you’ll receive quarterly reviews, service calls and repairs, planned and ongoing maintenance and parts and materials all included in a fixed annual budget.

Performance-based Maintenance and Upgrades: Under this plan we will provide a thorough maintenance review with your internal team to prioritize specific maintenance and upgrades needed for the year. Only those projects will be budgeted and included in one fixed, annual cost.

On-Site/Resident Technicians: When you need the value of a full time resident technician at your site.

-

Filtration and Air Dilution

The following strategies have been shown to reduce the transmission of infectious diseases through airborne particles. While many technologies claim to increase occupant health and safety, those listed below have solid evidence to support a substantial enhancement in the health and well-being of your facility.

Implementing these strategies have minimal upfront costs, but these minor additions can be highly leveraged for occupants’ health and safety.

Dilution Airflow: Reduces the concentration of infectious agents by increasing the amount of outside air brought into the occupied space. Dilution does not destroy the microbes but rather it reduces their concentration by spreading them over a large volume of air. This is something that can be addressed while performing HVAC and Controls maintenance and service by manually adjusting the dampers or economizers on your buildings ventilations systems (currently encouraged by the CDC).

An engineering review can help identify controls strategies and adjustments to bring in more Outside Air and to increase the air changes. Return with Confidence: Enervise Building Health Report

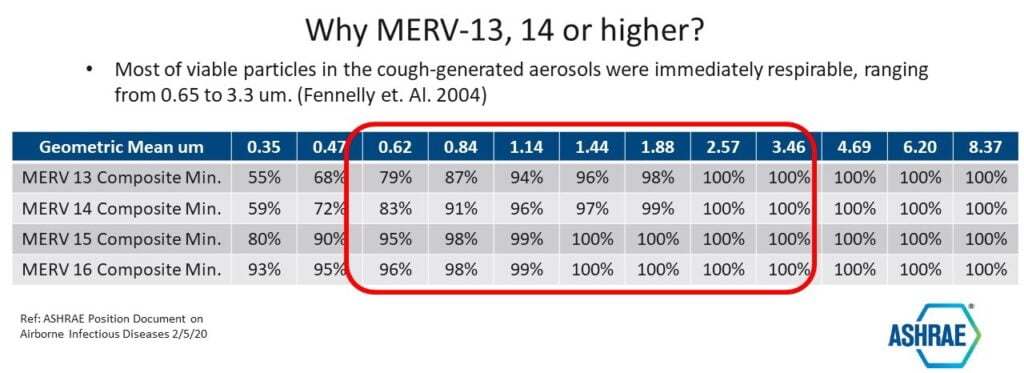

Filtration Increased Mechanical Filtration Efficiency: Reduces the concentration of infectious agents by passing the air through high efficiency air filters that trap bacteria and viruses, removing them from circulation MERV 13, 15 and 16.

There is significant evidence of health benefits for higher filtration strategies. ASHRAE Standard 62.1 requires minimum MERV 8 filters for commercial buildings

- Benefits of MERV 13 Filtration and Higher

- Proven to reduce risk of infectious diseases

- LEED credit

- Established industry efficiency rating standard

See other options for Ionization and UVGI under our Air Purification page.

Contact our experts today to see what type of filtration program will work for you or how we can assist you with air dilution solutions!

- Benefits of MERV 13 Filtration and Higher

-

Solid Chemistry Water Treatment

Enervise provides proven solid chemistry water treatment products to optimize water conditions using innovation & technology supporting cooling towers, boilers, and closed loop systems. Enervise solid chemistry delivers results with the utmost safety, savings and sustainability.

With solid chemistry, you will experience all of the benefits of a well-run water treatment program, plus additional benefits, such as:

- No dangerous spills

- Reduced shipping costs

- Reduced workplace injuries

- Elimination expensive storage constraints

- No disposal fees or hassles

- Zero contribution to landfills

Solid chemistry products are developed and manufactured using the EPA’s Twelve Principles of Green Chemistry, emphasizing safety, efficiency, and conservation of resources.

Upgrade to safe and sustainable solid chemistry water treatment & discover the benefits

- Increased savings

- Improved safety

- Sustainability

- Easy transport to difficult to access locations

- Less frequent delivery – Less refills required

- Maximize floor space

- LEED potential

Learn More Here

-

Boiler Maintenance Best Practices

Knowledge of how your boiler operates and conducting regular maintenance is vital to the life of your boiler as well as the safety of your employees and building occupants. Neglecting proper care of your boiler can happen when small changes go unnoticed over time. The results can be detrimental, or even catastrophic. However, implementing a few boiler maintenance best practices can help you to stay proactive to ensure the safe and efficient operation of your commercial boiler.

Keeping a Daily Log

Each day someone should routinely update the operating and maintenance logs of daily tasks. This is vital to the longevity of the boiler as it will give you a better understanding of the boiler’s operation, and will give clear indication when something is not functioning correctly. The boiler’s operating conditions often change slowly overtime making it hard to detect issues. This is not only harmful to the boiler, but could lead to dangerous boiler accidents.Creating a Baseline of Metrics

The daily log also helps establish a baseline of metrics to better understand the performance of your boiler. This baseline will help you to stay proactive, and acts as a compass when making maintenance and repair decisions. If the boiler logs begin changing over time, then you will have a better understanding of the source of the problem and how to remedy the issue.Develop a Maintenance Schedule

Developing a routine maintenance schedule with specified maintenance tasking is another best practice when maintaining your boiler. There are maintenance tasks that should be performed weekly, monthly, semi-annually, and annually. Each task will prevent various issues from arising. Whether it is maintaining piping in order to keep it from scaling, or preventing sludge build up, or maintaining the burner to ensure efficiency, you should have a timely and well documented schedule to keep things running safely and efficiently.Consult with a Professional

Finally, it is always a good idea to consult with a professional to ensure everything is working properly. Companies that specialize in boiler maintenance, repair, and installation can provide a high level of service increasing efficiency and, more importantly, increasing safety.The Boiler Group from Enervise

Enervise maintains and services boiler rooms. We have the depth of experience in the Enervise Boiler Group of technicians to be able to maximize boiler efficiency, and to insure safe and reliable operation of your boiler. Whether you need maintenance, repair, or would even like to build a new boiler room from scratch, Enervise can meet your needs and Do It Right.Expertise – We bring the “A” team of qualified technicians from within our Boiler group with the depth and expertise to service any size Hot Water or Steam Boiler.

Trusted – We know your building, have your back, and know what you expect to keep hot water or steam flowing in your building.

Response – Quick, fast response 24/7 when needed to keep your boiler on line. Need a backup Boiler? Our team can pipe in temporary rental boilers to get you back on line fast.

References – Talk to our customers. We’ll provide you with happy and enthusiastic boiler customer references that you can call. We are thankful that most of our customers have trusted us as their service provider for their boiler or central plant for well over 12 years on average.

The Boiler Technician group from Enervise provides:

- Tenured Experience

- Certified Factory Trained Technicians knowledgeable on Hot Water and Steam Fire tube boiler, Water tube boiler, Packaged and Atmospheric Boilers.

- Quick Response 24/7

- Boiler Maintenance programs

- Complimentary Support to your Maintenance team

- Repairs & Service of all major Commercial and Industrial Boiler brands

- Burners & Control System Repair and Replacement

- Annual Insurance Inspections

- New & Used Equipment Installations

- Pumps & Piping Systems – Steam, Fuel, Water, Etc.

- Deaerators, Feed tanks, & Economizers

- Re-tubing & Refractory Repairs

- Energy Retrofits and Boiler Replacement

-

Chiller Maintenance Best Practices

Chillers are often the single largest capital asset in a commercial or industrial building. Understanding how your building works to optimize your chiller plant is critical to both the comfort and efficiency of your building or facilities. Proper maintenance is essential to ensure your chiller meets the needs of your building and to ensure the longevity of this valuable asset.

Keeping a Daily Log

One of the most important best practices you can employ is keeping a daily log of your chillers operating performance. This log will help your company to keep a close eye on performance trends allowing you to proactively maintain your commercial chiller. The log gives you baseline metrics that help you to understand when your chiller is operating at peak efficiency. More importantly, the log will clue you into when there are issues with your chiller and the possible root cause.Utilize Monitoring to Stay Proactive

With the introduction of automated systems and remote monitoring, it has become easier for commercial facilities to continuously monitor their chiller’s performance. Facility managers are now able to make changes on a continuous basis keeping commercial chillers even more efficient.Develop a Maintenance Schedule

One of the best things you can do to keep your commercial chiller working at optimal performance is keeping a consistent maintenance schedule. There are maintenance tasks that should be performed weekly, monthly, semi-annually, and annually. Cleaning your heat tubes is a good example of a maintenance task that should be performed on a consistent basis in order to ensure adequate heat transfer efficiency.Consult with a Professional

Finally, it is important to consult a professional one a regular basis to ensure that your chiller is working as expected. A professional can bring their technical knowledge about chillers, provide maintenance services, adjust tasking, manage repair, or upgrade commercial chillers maximizing efficiencies and saving in operating costs.

The Chiller Technician Group from Enervise

We can maintain and service your Chillers and central plant equipment. We guarantee to “Do It Right” providing you with the best solutions possible with today’s technology. The Enervise difference is palpable when you meet your Enervise Chiller specialist. Whether you have a Centrifugal, Rotary Screw, or Reciprocating compressor chiller, we have the depth of experience in the Enervise Chiller Group of technicians to be able to maximize Chiller efficiency, and to insure reliable operation.Expertise – We bring the “A” team of qualified technicians with the depth and expertise to service any size water or air cooled chiller.

Trusted – We know your building, have your back, and know what you expect to Do It Right to keep cold water flowing in your building.

Response – Quick, fast response 24/7 when needed to keep your chillers on line.

References – Talk to our customers. We’ll happily provide you with happy chiller customer references that you can call. We are thankful that most of our customers have trusted us as their service provider well over 12 years on average.

The Enervise Chiller Tech group provides:

- Tenured Experience

- Certified Factory Trained Technicians

- Quick Response 24/7 – Emergency Services & Repair

- Chiller Maintenance programs – with specialized maintenance tasking for Centrifugal, Rotary Screw, and Reciprocating Semi Hermetic Compressors

- Complimentary support to your maintenance team

- Repairs & Service of all major brands – York, Daiken, McQuay, Trane, Carrier and others

- Chiller plant optimization

- Reciprocating, Rotary Screw and Centrifugal Compressor services and rebuilds

Balancing services & vibration analysis - Pumps & Piping Systems

- Cooling towers and support systems

- Spectroscopic Oil sampling refrigerant analysis

- Eddy Current testing

- Re-tubing

- Control Panel Retrofits & Starter Upgrades

- Energy Retrofits and Chiller replacement

- Tube Cleaning

- Evacuation & Dehydration

- Motor Insulation & Testing

-

Your Quality Technical Team

You can trust the expertise of our factory-trained technicians, most of whom have worked in the industry for at least 15 years or longer. Through ongoing training and years of experience they understand your equipment and how to keep it running smoothly and efficiently. When an issue arises our team always goes above and beyond to make certain things are thoroughly resolved each and every time.

-

On-Site Expertise

Enervise employs only the best! Rest assured that we provide trained, experienced and professional personnel to work on-site at a fraction of the cost of mobile technicians. Our techs can manage your systems independently or fully support and assist your existing staff.

We offer a range of on-site services to keep your facility thriving—within budget and without headaches. Contact us today for more information about:

- HVAC & General Maintenance Mechanics

- Administration

- Maintenance Management, including:

Computerized Maintenance Management Systems (CMMS)

Our experienced team is here to assist you with your facilities management challenges

Our experienced team is here to assist you.

FOR IMMEDIATE SERVICE, PLEASE CALL 800-845-4839